Chloroprene adhesive, commonly known as neoprene adhesive, is a high-performance bonding solution known for its exceptional flexibility, strong initial tack, and durability. It is widely used in footwear manufacturing, repair, and other applications where fast-setting and heat-resistant bonds are essential. Chloroprene adhesives are ideal for bonding materials that require some flexibility, such as leather, rubber, and certain synthetic fabrics.

Chemical Composition: Based on chloroprene rubber, which offers strong initial bonding and high elasticity.

Cure Time: 10-15 minutes for initial tack, with full strength achieved after 24 hours.

Viscosity: Medium to high viscosity, suitable for spreading evenly with a brush.

Tensile Strength: Up to 2500 psi, providing strong adhesion for demanding applications.

Temperature Resistance: Withstands temperatures from -20°C to 80°C, making it suitable for a range of environmental conditions.

Shelf Life: 9-12 months when stored properly in a sealed container.

Specific Use Cases: Ideal for bonding rubber soles, leather uppers, and synthetic materials in footwear production and repairs.

Industry Use: Commonly used in the footwear, upholstery, automotive, and construction industries for bonding flexible materials.

Materials Compatibility: Works well with leather, rubber, wood, foam, metal, and certain types of plastic and fabric.

Benefits and Advantages:

Strong Initial Tack: Allows for fast initial bonding, making it ideal for applications where quick assembly is needed.

Flexible Bond: Maintains elasticity even after curing, making it perfect for items like shoes that experience frequent bending and flexing.

Heat Resistant: Performs well in moderate heat conditions without losing its adhesive strength.

Water Resistant: Provides a waterproof bond, making it suitable for outdoor applications and products exposed to moisture.

Good Shear Strength: Withstands shear forces, making it reliable for long-lasting adhesion under stress.

Surface Preparation: Clean surfaces thoroughly with a suitable solvent to remove oil, dust, and debris.

Apply Adhesive: Spread an even layer of chloroprene adhesive on both surfaces using a brush or spatula.

Air Drying: Allow the adhesive to air dry for 5-10 minutes until it becomes tacky.

Press Surfaces Together: Press the surfaces together firmly, applying uniform pressure for a few seconds.

Curing Process: Let the bonded surfaces sit for at least 24 hours to achieve full bond strength, avoiding movement during this time.

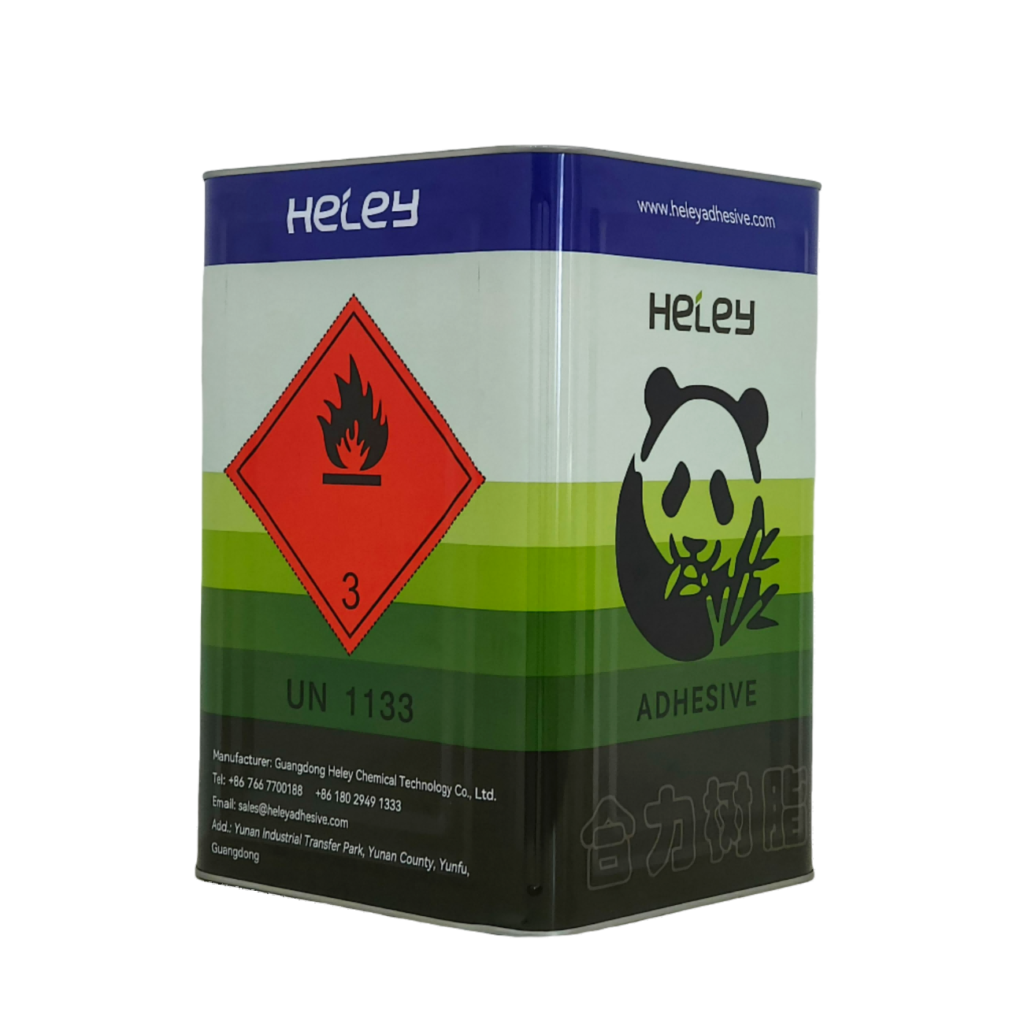

Safety and Handling:

Safety Precautions: Use gloves and safety goggles to protect skin and eyes from contact with the adhesive.

Ventilation Requirements: Apply in a well-ventilated area or use an extraction system to avoid inhaling fumes.

Disposal Instructions: Dispose of adhesive residue in compliance with local environmental regulations; do not discard into water systems.

Storage Guidelines: Store in a cool, dry location, away from heat sources and direct sunlight, to prevent premature curing.

Environmental Impact:

Sustainability Initiatives: Chloroprene adhesives are available in formulations that reduce VOC content for a lower environmental footprint.

Recyclability: Containers are recyclable when cleaned, supporting waste reduction efforts.

Non-Toxic Formulas: Some low-VOC versions are available for safer use indoors and reduced air pollution.

Sustainability Initiatives: Chloroprene adhesives are available in formulations that reduce VOC content for a lower environmental footprint.

Recyclability: Containers are recyclable when cleaned, supporting waste reduction efforts.

Non-Toxic Formulas: Some low-VOC versions are available for safer use indoors and reduced air pollution.

Common adhesives in footwear manufacturing include PU adhesives, grafted adhesives, chloroprene adhesives, spray adhesives, and synthetic rubber adhesives, each suited for specific applications.

Choose adhesives based on compatibility with shoe materials, such as leather, fabric, or rubber, considering factors like flexibility and durability. You can also contact our team for more details.

Solvent-based adhesives provide strong bonds and fast drying times, while water-based adhesives are more environmentally friendly and easier to clean.

Adhesive performance can be affected by climate; extreme temperatures or humidity may impact drying times and bond strength.

Safety precautions include working in a well-ventilated area, wearing gloves and masks, and following the manufacturer’s guidelines.

The shelf life of footwear adhesives typically ranges from 6 months to 2 years, depending on storage conditions and formulation.

If you need customized product or technical support, please click the button below. Our expert will come back to you within 24 hours.