Improving the bond strength in shoemaking process is a headache for shoemakers. The durability, flexibility, and waterproofing of shoes all depend on how well different materials stick together. However, not all materials bond easily—rubber, EVA, TPU, and leather each present unique adhesion challenges. This is where surface primers come into play.

But how exactly do they work? And what are the best practices for their use? In this article, we’ll explore:

-

The science behind primers—how they activate surfaces and improve adhesion.

-

Key applications in shoemaking, from rubber soles to synthetic uppers.

-

Emerging trends, including eco-friendly primers and advanced surface treatments.

The Science Behind Primers: Why They Strengthen Bonds

Surface Activation for Better Adhesion

Many shoe materials (like rubber and EVA) have low surface energy, making them resistant to adhesives. Primers chemically modify these surfaces, increasing their wettability so adhesives spread evenly and penetrate deeper.

-

Example: Chlorination (halogen-based primers) oxidizes rubber soles, creating polar groups that bond better with PU adhesives.

-

Alternative: Plasma treatment, an eco-friendly option, achieves similar activation without harsh chemicals.

Removing Contaminants for a Cleaner Bond

Dust, oils, and mold release agents can weaken adhesion. Primers:

-

Dissolve contaminants (solvent-based primers).

-

Etch surfaces (acid-based primers for rubber).

-

Improve mechanical interlocking by creating micro-roughness.

Chemical Bridging: The “Glue for the Glue”

Some primers contain coupling agents (e.g., silanes or isocyanates) that form strong chemical bonds with both the substrate and adhesive.

-

Example: Silane primers enhance PU adhesive bonding on TPU soles.

-

Example: Isocyanate primers improve rubber-to-fabric bonds in waterproof shoes.

Key Applications of Primers in Shoemaking

Rubber Soles: Chlorination vs. Eco-Friendly Alternatives

Improving the bond strength of rubber soles requires specialized approaches.

-

Traditional method: Chlorine-based primers (effective but environmentally concerning).

-

Modern solutions: Water-based primers, plasma treatment, or laser etching.

These methods all focus on creating surface conditions that maximize adhesive penetration and chemical bonding.

EVA Midsoles: Flame Treatment & Primers

The smooth, non-porous nature of EVA makes improving the bond strength particularly challenging.

-

Flame treatment temporarily increases surface energy.

-

Primers for water-based adhesives ensure long-term durability.

Chemical primers are essential for maintaining high bond strength throughout the shoe’s lifespan.

TPU & Plastic Components: Isocyanate Primers

In high-performance footwear where improving the bond strength is critical, isocyanate-based primers create molecular bridges between materials.This technology is particularly valuable for improving the bond strength in waterproof constructions and athletic shoes subjected to extreme conditions.

Leather & Synthetic Uppers: Degreasing Primers

Natural leather contains oils that can repel adhesives, while synthetic materials often have surface treatments that inhibit bonding. Solvent-based primers effectively remove these barriers.

- For oily leathers, degreasing primers prepare the surface for optimal adhesion.

-

For synthetic microfiber, primers ensure strong PU or latex adhesive bonds.

Proper primer application ensures the upper stays securely attached to the sole unit.

Best Practices for Primer Application

To maximize bond strength:

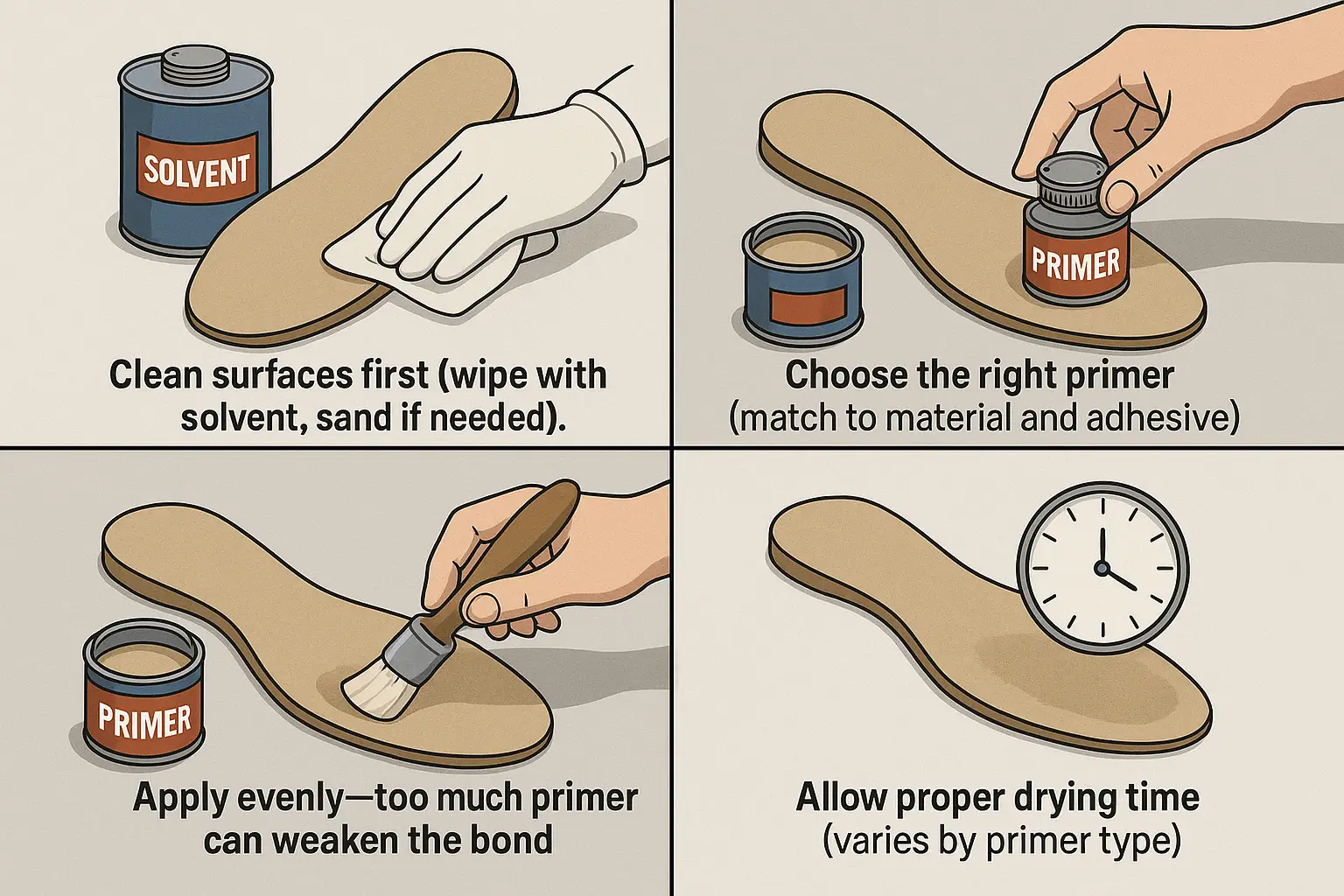

- Clean surfaces first (wipe with solvent, sand if needed).

- Choose the right primer (match to material and adhesive).

- Apply evenly—too much primer can weaken the bond.

- Allow proper drying time (varies by primer type).

Future Trends: Sustainable & High-Tech Primers

-

Water-based primers (reducing VOC emissions).

-

Plasma & laser treatments (chemical-free activation).

-

Smart primers (self-healing or moisture-resistant properties).

Final Thoughts

Surface primers are the unsung heroes of shoemaking, ensuring shoes stay intact through wear and tear. By understanding their role—surface activation, contamination removal, and chemical bridging—manufacturers can produce more durable footwear.

As the industry shifts toward eco-friendly adhesives and advanced treatments, primers will continue evolving, offering even stronger, greener bonding solutions.